The uncut diamonds that have just been extracted from the earth's rock are very far from the kind we expect when we think of diamonds. These minerals have an uneven, asymmetrical shape, more like fragments of ice. In this state, diamonds do not give absolutely no shine, which we are used to from jewelry.

Before rough diamonds become diamonds, they go through a number of stages:

1. Mining

Diamonds are extracted from natural deposits such as mines and rivers, as well as from the seabed. Specialized companies and mining enterprises produce diamonds using complex and massive machinery and a lot of hard human labor.

2. Cleaning

After mining, the diamond-bearing rock (kimberlite) undergoes the process of crushing, cleaning from dirt, clay and other impurities so that only transparent diamonds remain.

3. Classification

At this stage, diamonds are sorted by quality and characteristics (color, clarity, weight and shape). This allows you to determine which diamonds are suitable for use in jewelry, and which will be used for technical purposes (production of abrasive materials, drills, and other high-strength tools).

4. Marking and Cutting

Cutting specialists use special programs to calculate the maximum weight of the final diamond and the correct angles of refraction of light, which maximize the inner fire of the diamond and give the diamonds a familiar look to everyone.

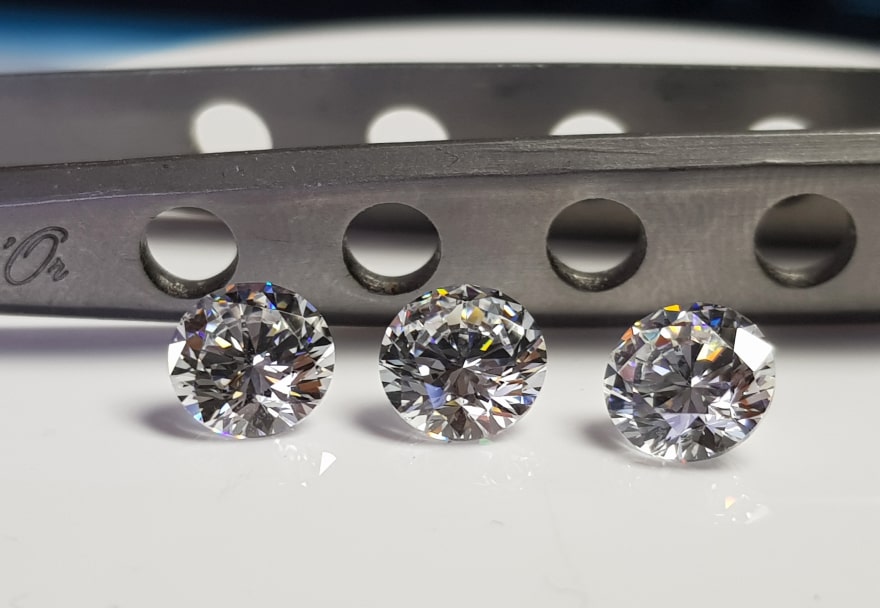

5. Polishing

After cutting, the diamonds are polished to give the surfaces perfect transparency and radiance. This stage allows you to maximize the inner fire of the diamond and make it ready for use in jewelry.

6. Certification

After completion of the cutting and polishing process, diamonds are subject to certification by gemological laboratories such as GIA, AGS or HRD. Certificates contain information about the characteristics of a diamond, such as 4C": Color, Clarity, Cut and Carat weight, which allows buyers to understand the quality and value of the stone.